Export of Polyethylene Pipe Grade Compounds:

The need for raw materials, such as polyethylene pipe grade compounds, has expanded dramatically due to the global construction industry’s growth. These compounds, produced from polyethylene with various compositions and different physical and chemical specifications, are used in the production of various pipes for various applications including water, gas, and sewage transmission. The industry of producing polyethylene pipe grade compounds is rapidly growing as a vital sector of the plastics industry. This industry has been able to improve the quality and performance of its products by utilizing innovative technologies and adhering to international standards. In recent years, the volume of exports of polyethylene pipe grade compounds from producing countries to consumer countries has sharply increased. This increase in exports has not only helped boost the industrial revenue of producing countries but has also created new business opportunities and strengthened international relations. Top of Form

Turkey and Uzbekistan are considered two important markets in the Middle East and Central Asia region and are notable destinations for the export of polyethylene pipe grade compounds. Turkey, with its dynamic construction industry and other sectors such as automotive and electronics, provides a highly suitable market for the export of these products. Uzbekistan, as one of the developing countries in Central Asia, presents an attractive market for the export of polyethylene pipe grade compounds from Iran, due to diverse needs in the construction industry and various other industries.

Considering these factors, exporting polyethylene pipe grade compounds to Turkey and Uzbekistan can be seen as a favorable opportunity for the development of polymer industry businesses in these regions.

Petro Nour Mehr Trading Company has the capability to supply PE100 polyethylene compound with the best quality and price.

Consultation on Polyethylene Pipe Grade Export

Petro Nour Mehr Trading Company, with years of experiences in exporting polymer materials, proudly offers consultancy services in the field of exporting polyethylene pipe grade. Leveraging our expertise and technical knowledge in the polymer industry, we are prepared to provide comprehensive and specialized consultancy services for exporting polyethylene pipe grade to various global destinations.

Our services include:

Technical Consultation: Providing consultancy on the characteristics and various applications of polyethylene pipe grade, as well as standards and regulations relevant to destination countries.

Export Process Support: Offering technical and operational support in all stages of the export process, including transportation selection, packaging, and customs procedures.

Follow-up and After-Sales Support: Providing follow-up and customer support services after product delivery to ensure complete customer satisfaction.

Polyethylene (PE100) producing petrochemical plants:

Among the 68 active petrochemical plants inside the country, Jam Petrochemical, Shazand, Ilam, Amir Kabir, and Aryasasol produce polyethylene pipe grade. This polymer grade is marketed under various trade names. The polyethylene pipe grade of Jam Petrochemical is marketed under the trade name CRP 100N, Shazand Petrochemical’s grade under the trade name PE100 BLACK, Ilam Petrochemical’s grade under the trade name HD7700M, Amir Kabir under the trade name EX3, and Aryasasol under the name PE80+. Among these petrochemical plants, Jam Petrochemical has allocated a larger share to itself compared to other petrochemicals. In 1401, Jam Petrochemical succeeded in registering a production record of over 387 thousand tons of PE100 products. The produced polyethylene of this petrochemical plant is available in two forms: white and black granules. Below, you can see the analysis and datasheet related to each of these petrochemical plants.

PE 100 Compounds Suitable for Pipe Production:

For the production of polyethylene pipes according to international standards, it is better to use compounded polyethylene materials. This is because by adding additives and black pigment, the properties of virgin petrochemical materials (natural) can be enhanced. For instance, materials containing black pigment are utilized to produce polyethylene pipes for the transport of water, as this results in great performance and efficiency. This product is derived from petroleum materials, and they are combined with pigments and other ingredients to create polyethylene compounds. During the process of converting polyethylene into polyethylene compounds, the properties of this material, such as its strength and resistance, increase because polyethylenes have lower strength in their normal state, but when converted into polyethylene compounds, they exhibit higher resistance to sunlight, stresses, and other environmental factors.

Figure 1. Schematic of the compound process of mixing virgin materials with carbon black

The compound produced here possesses the necessary capability and quality for the production of water and gas pipes and complies with the required standards. The components forming the polyethylene compound include virgin materials, filler, and antioxidants. These materials are combined in a precisely defined ratio inside the granulator machine, and the produced granules are ready for the production of polyethylene pipes. Due to these characteristics, this compound has created significant competition in both domestic and international markets. The generated compound can be used to build high-pressure pipes because of its high and desired qualities, as demonstrated by the gas transmission pipes displayed.

Figure 2. The polyethylene gas pipe produced with compounded materials

Advantages and Characteristics of Polyethylene Compounds:

As previously indicated, polyethylene compounds—which are produced by combining virgin petrochemical materials with additives that provide the required properties for pipe production—play a critical role in the manufacturing of plastic pipes and pipe fittings because of their high resistance and flexibility. Therefore, polyethylene compounds have the following advantages:

- Due to the filler used, they are resistant to sunlight.

- They have consistent and completely uniform quality.

- The materials used, such as filler and antioxidants, have specific amounts and comply with standards.

- The price of compound products is reasonable and competitive in both domestic and international markets.

Supply and Demand of Polyethylene Pipe Grade Compounds

Due to the continuous growth of the construction industry globally and the ongoing need for raw materials used in this sector, the demand for polyethylene pipe grade compounds has significantly increased. This demand is driven by the expansion of construction, water and sewage distribution networks, gas, and other urban infrastructures. The construction, gas and oil, water and sewage, agricultural, and other pipe-related industries are the main sources of demand for polyethylene pipe grade compounds. These industries rely on polyethylene pipe grade compounds to meet their needs for transporting fluids and gases. Additionally, the supply of polyethylene pipe grade compounds by manufacturing companies has increased to meet market demands at both local and international levels. These companies strive to provide high-quality products adhering to international standards by employing advanced production technologies and quality control measures. Given the growing demand and high production capacity of polyethylene pipe grade compounds, the supply of these products usually meets market needs satisfactorily, covering both domestic and international markets.

The Price of Polyethylene Pipe Grade Granules

The price of polyethylene pipe grade granules holds significant importance in global markets. Polyethylene pipes are among the most essential products used in industries such as water and sewage, agriculture, oil and gas, and construction. A number of variables, including as the price of crude oil, supply and demand in the international market, the cost of transportation, and inflation rates, affect the price of polyethylene pipe grade granules. In recent years, fluctuations in crude oil prices and market dynamics have had a notable impact on the price of polyethylene pipe grade granules. Additionally, demand and supply of the product in local and global markets play a crucial role in price determination.

For example, the price of polyethylene pipe grade granules may rise in response to increased demand for polyethylene pipes in the water and sewage industry brought on by the building boom and urban growth. Furthermore, transportation costs also affect the pricing of polyethylene pipe grade granules. An increase in transportation costs due to rising fuel prices can result in higher overall product costs. Consequently, the price of polyethylene pipe grade granules is continuously influenced by various factors and may undergo significant changes over time.

The Use of Polyethylene in the Pipe Industry

The use of polyethylene in the pipe industry is one of the most important and widespread applications of this material. Polyethylene is a highly preferred material for long-lasting, high-performing industrial and agricultural pipes because of its special qualities, which include flexibility, resistance to corrosion, chemical and temperature insulation, and good weldability.

High-Density Polyethylene (HDPE) is particularly suitable for irrigation pipes, sewage pipes, and gas pipes due to its high resistance to pressure and impact, high strength, and impermeability to water. The use of polyethylene in the pipe industry improves the performance of piping systems, reduces maintenance and repair costs, and minimizes environmental pollution.

Because of its special physical and chemical characteristics, polyethylene is used in a wide variety of applications within the pipe industry. These points will be explained in more detail below.

- Flexibility: Polyethylene exhibits high flexibility, making it suitable for applications requiring pipe bending and flexibility. This flexibility allows the pipes to withstand temperature and pressure changes that may occur in various industries.

- Corrosion Resistance: Polyethylene has good resistance to corrosion, making it suitable for use in environments exposed to chemical pressures or contaminated environments.

- Impermeability to Water and Chemicals: Polyethylene is a type of plastic material with low permeability to water and chemicals. This feature makes it suitable for use in irrigation, sewage, gas pipes, and even in chemical industries.

- Resilience and Strength: Polyethylene has high mechanical strength and resilience. These properties make it suitable for use in piping systems requiring high flexibility and strength.

- Resistance to Breakage and Wear: Due to its high resistance to breakage and wear, polyethylene has a longer lifespan, making it a stable and economical option for piping systems.

Considering these characteristics, polyethylene is recognized as one of the most versatile and reliable materials in the pipe industry, ensuring improved performance and efficiency of piping systems.

Comparing Polyethylene Pipes and Metal Pipes:

- Weight and Flexibility: Polyethylene pipes are typically considerably lighter than metal pipes and also exhibit greater flexibility. This flexibility makes them suitable for installation in conditions where unique bends or changes in the pipe path are required.

- Corrosion Resistance: Polyethylene pipes have very good resistance to corrosion, whereas metal pipes may be susceptible to corrosion and rust, especially in humid or chemical environments.

- Cost: Generally, polyethylene pipes have lower costs for purchase and installation compared to metal pipes. Additionally, their maintenance and repair costs are also lower.

- Lifespan: Polyethylene pipes usually have a longer lifespan and generally require less frequent replacement compared to metal pipes, which may deteriorate faster due to corrosion and rust.

- Flexibility in Design: Polyethylene pipes allow flexibility in design and shaping, whereas metal pipes are not easily reshaped and require welding and specialized tools. On the other hand, one of the advantages of metal pipes can be their higher resistance to pressure and temperature. However, this advantage comes with higher costs for production and installation. Conversely, polyethylene pipes may be less resistant to high heat and pressure, but for many applications, this issue is not significant.

Export Volume of PE100 in Iran

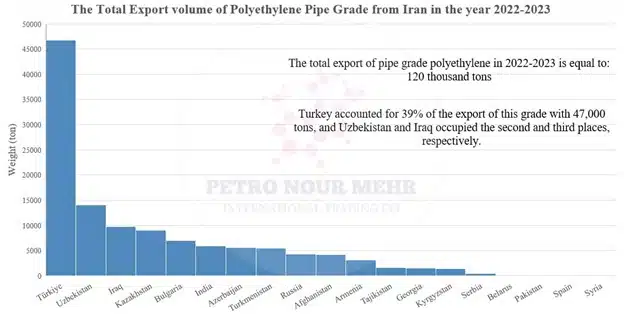

According to statistics published by the Statistical Center of Iran and the Chamber of Commerce, Iran’s export volume in the year 1401 was 53 billion dollars, out of which 18 billion dollars were attributed to the petrochemical industry. Most of Iran’s exports were directed to China, Iraq, Turkey, and the United Arab Emirates, respectively. Among petrochemical materials, the export volume of polyethylene grade pipe with HS CODE: 39012020 was reported as 149 million dollars in 2022-2023, which is a considerable figure. The majority of exports of this grade were to China, Iraq, Russia, and Turkey. Additionally, the export volume of high-density polyethylene compound with a density of 0.94 g/cm^3 and HS CODE: 39012059 was estimated at 65 million dollars in 2022-2023. The figure below illustrates the export volume of this grade to different countries.

Figure 3. The amount of heavy polyethylene (PE 100) exports from Iran to various countries in the year 2023-2022