Expandable polystyrene (EPS)

This polymer material is typically divided into two main groups: combustible and non-combustible. If an this material ceiling block shows resistance to fire, it means it is of the non-combustible type. However, it should be noted that its resistance to fire is not very high, and if the fire continues for a long time, it may ignite. Signs that indicate the ignition of this material include a yellow flame, material charring in the flame, black smoke, and a smell similar to natural gas.

EPS, known as “Yunolit” in Iran and globally as EPS, is a white polymer that is mixed with a foaming agent during the manufacturing process to acquire unique properties. You are probably familiar with the name “Yunolit” as it is very common in Iran.

These types of polystyrenes have become a preferred choice for packaging and insulation in various industries due to their lightweight, low thermal conductivity, high resistance to compression, and excellent impact absorption. The price of EPS, considering these features, is cost-effective.

EPS, short for expandable polystyrene, is a polymer material produced in a rigid and lightweight form. It is made from the monomer styrene, which is polymerized to create it. this material is used in many industries, including packaging, insulation, lightweight construction, impact protection, and more. Due to its lightweight and insulating properties, it is used in packaging for sensitive products and in the construction of structures requiring thermal insulation.

To obtain more precise information on Polystyrene (PS) prices or product purchases, it is better to contact the Petro Nour Mehr Company’s sales department.

For more accurate information regarding prices or purchasing the product, it is better to contact the sales department of Petro Nour Mehr Company.

Analysis of EPS grades

You can find the list of GPPS & HIPS products in the table below:

To view other polymer products, you can click here.

EPS Manufacturers in Iran

Sahand, Baniar Petrochemicals and other domestic factories are producers of this chemical material in Iran.

These units are among the largest EPS producers in Iran and play a significant role in supplying domestic needs and exporting this material to global markets.

EPS Manufacturers Worldwide:

This material, also known as foam polystyrene, is a type of plastic material widely used in various industries, including packaging, construction, and transportation. Some of the largest EPS manufacturers worldwide include:

- Sunpor Kunststoff GmbH: A German company specializing in the production of polymer materials and polystyrene products. The company is primarily engaged in manufacturing polymer materials for the construction, automotive, packaging, and other consumer industries. Its products include thermal insulation materials, building panels, and related thermal insulation products.

- Alpek: This company is involved in the production and sale of polymer materials, petrochemicals, and synthetic fibers. Based in Mexico, Alpek manufactures polyester, polypropylene, polystyrene, and other petrochemical products. Additionally, Alpek produces and sells synthetic materials such as polyester and polypropylene for use in various industries including packaging, automotive, and electronics.

This non-combustible polystyrene is a highly versatile material used in various industries. Some of its applications include:

- Packaging: This material is used as packaging material to protect transported goods, including electronics, household appliances, and food products.

- Automotive parts manufacturing: Due to its lightweight nature and compatibility with manufacturing processes, EPS is used in producing both interior and exterior automotive components.

- Modeling: It is used as a lightweight and easy-to-carve material for modeling purposes, commonly in construction industries and production of artificial products.

- Interior decorations: This polymer material is utilized as a malleable and lightweight material for interior decorations such as tiles, columns, and other ornaments.

- Shock protection: Some EPS products are used to prevent damage and structural harm against mechanical shocks and impacts.

- Disposable containers: Certain disposable items like cups and packaging containers are made from this polymer.

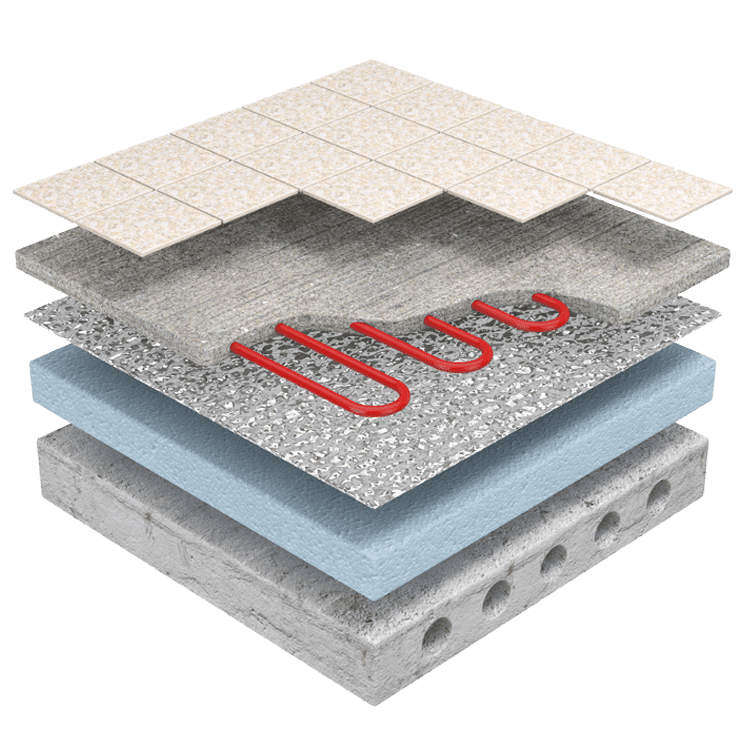

- Construction industry: Non-combustible and resistant expanded polystyrene, commercially known as XPS or EPS, is one of the most widely used materials in the construction industry. Due to its unique properties such as heat and moisture resistance, it is extensively used as thermal insulation. Additionally, it acts as a sound insulator and reduces sound transmission between indoor and outdoor spaces. With its closed-cell structure and high density, it restricts moisture and water penetration into the building and serves as a cold base insulation in areas in contact with cold surfaces, such as building foundations. Moreover, it helps improve the performance and efficiency of waste management systems and may be used in the construction of building components like ceiling and wall tiles. The use of non-combustible and resistant expanded polystyrene can enhance thermal, acoustic, moisture, and environmental resistance properties of buildings under different environmental conditions. The selection and installation of these materials should be done carefully and according to the manufacturer’s recommendations and guidelines to fully benefit from their properties.

As a multifunctional material, the uses of this material continue to expand and evolve, with new innovations potentially providing new applications.

Storage Conditions for EPS:

These polymer materials can be stored under various conditions, but there are some guidelines for better preservation of their quality:

- It is best to store these materials in a cool and dry environment, with the optimal storage temperature being below 50 degrees Celsius.

- Protect the material from direct sunlight and UV light, as these lights can cause changes in its physical and chemical properties.

- This polymer material react with certain chemicals such as solvents and acids. Therefore, it is better to avoid direct contact with these types of materials.

- Make sure the material has protection from impacts and scratches while being stored and transported, since physical harm may cause modifications to its mechanical and structural characteristics.

- The packaging of these materials should be made of suitable materials that protect against environmental changes and prevent water and moisture penetration into the packaging.

- For some specific products, special storage conditions may be required. In this case, refer to the manufacturer’s guidelines.

Packaging for EPS:

This polymer material granules can be packaged and exported using a variety of techniques, depending on the product’s needs, the environment, and ease of export shipping. Below are some common methods for packaging and exporting polystyrene granules:

- Packaging in Jumbo Bags: This method is common for packaging EPS granules, where the granules are packed into large bags with varying capacities (usually between 500 to 2000 kilograms). These bags, besides protecting the product from contamination and moisture, are suitable for road, sea, and air transportation.

- Packaging in Small Bags: In this method, the granules are packed into smaller bags with a capacity of about 20 to 25 kilograms.

- Use of Pallets: Polystyrene granules are usually packed on large pallets for transportation purposes.

When choosing the right packaging and export techniques for EPS granules, meeting international packaging standards, labeling, and transportation requirements can be essential. Ensuring that the product is protected during shipment against shocks, moisture, and environmental damage is also crucial.

- Buy from a reputable and authorized supplier that holds necessary certifications and guarantees quality.

- Compare the prices of these materials in different markets and compare them with the global market price.

- Examine the sales conditions regarding quantity, delivery time, packaging, transportation methods, and payment terms.

- If you intend to import EPS from foreign countries, investigate customs and legal regulations and comply with export and import regulations.

- Contact Petro Nour Mehr Company to obtain the most suitable export price based on your conditions.

- After signing the contract, you can place your order.

- Secure and suitable payment methods according to customer preferences are provided by the company.

- Then, the loading stage is completed by selecting and introducing a transport company.

- Necessary documents for customs clearance at the destination city are also provided to customers by Petro Nour Mehr Company.

How much we know about EPS:

This material exhibits several characteristics that make it a popular choice in various applications:

- Lightweight: It is exceptionally lightweight, making it easy to handle, transport, and install.

- Insulation: This material has excellent thermal insulation properties, helping to maintain indoor temperatures and reduce energy consumption in buildings.

- Impact Resistance: It can absorb and distribute impact energy effectively, making it suitable for protective packaging and cushioning applications.

- Buoyancy: This material is buoyant and resistant to water absorption, making it suitable for use in flotation devices and marine applications.

- Versatility: It can be easily molded and shaped into various forms and sizes to meet specific design requirements.

- Cost-Effectiveness: This polymer material is a cost-effective material compared to alternative insulation and packaging materials.

- Chemical Resistance: This material is resistant to most chemicals, making it suitable for applications where exposure to chemicals is a concern.

- Recyclability: It is recyclable, and many manufacturers offer recycling programs to reduce environmental impact.

Overall, the combination of lightweight, insulating, and impact-resistant properties makes this polymer material a versatile material used in construction, packaging, insulation, and other industries.

Comparison between EPS and GPPS:

Expanded Polystyrene (EPS) and General Purpose Polystyrene (GPPS) are two different forms of polystyrene with distinct characteristics and applications. Here’s a comparison between EPS and GPPS:

Structure and Appearance:

- EPS: This material is a cellular plastic material produced from expanded polystyrene beads. It has a foamy, lightweight structure with closed cells.

- GPPS: GPPS is a rigid, transparent plastic with a solid structure. It is typically clear or translucent and lacks the foamy texture of EPS.

Physical Properties:

- EPS: It has excellent thermal insulation properties, low density, and high buoyancy. It is lightweight, rigid, and offers good impact resistance.

- GPPS: GPPS is rigid and brittle with high clarity and gloss. It has good dimensional stability and is easy to process, but it lacks the thermal insulation properties of EPS.

Applications:

- EPS: This material is commonly used in packaging, insulation, construction, and crafting. It is widely used for packaging fragile items, thermal insulation in buildings, lightweight fill material, and as a core material in composite panels.

- GPPS: GPPS is often used in applications where transparency, clarity, and aesthetics are important. It is commonly found in food packaging, disposable cups and utensils, cosmetic packaging, CD cases, and office supplies.

Environmental Impact:

- EPS: It foam is non-biodegradable and can persist in the environment for a long time if not properly managed. However, it is recyclable, and many recycling facilities accept this material for processing into new products.

- GPPS: GPPS is also non-biodegradable and can contribute to environmental pollution if not disposed of properly. Like EPS, it is recyclable, but recycling rates may vary depending on local facilities and infrastructure.

In summary, while both EPS and GPPS are forms of polystyrene, they have different structures, properties, and applications. EPS excels in insulation, packaging, and lightweight construction, while GPPS is valued for its clarity, transparency, and aesthetic appeal in various consumer products and packaging materials.